Everyday routes, extraordinary control

How Package Express tested a new way of cold chain operations across the Texas heat.

January 29, 2026

The challenge

In Texas, cold chain logistics doesn't get any favors from the weather.

Package Express supports daily milk runs and urgent STAT deliveries for hospitals, pharmacies, and labs across the state. Their routes cover long distances. The heat is relentless. And the temperature requirements vary, often within the same day.

On a typical route, drivers manage:

Three temperature ranges: frozen (-20°C), refrigerated (2–8°C), and CRT (15–25°C)

Multiple stops with frequent lid opens

Manual prep with gel packs and dry ice, requiring freezer space, advance planning, and constant replenishment

As volumes have grown, so have operations. The team wants more visibility, fewer variables, and a way to maintain compliance without adding complexity for drivers.

That led to a pilot: can active, reusable cooling simplify day-to-day operations and hold up on real routes, in real heat?

The approach

Package Express partnered with Artyc to run a 3-month pilot using battery-powered, IoT-enabled coolers on live courier routes.

The pilot ran on everyday deliveries, not lab tests or controlled environments.

Pilot setup:

6 Artyc coolers deployed across milk runs and STAT routes

Coolers continuously logged temperature, location, battery status, and lid opens

Drivers charged units overnight: ready to go each morning, no special handling required

What happened on the road

Over three months, the coolers were put to work exactly as intended: repeatedly, across demanding conditions.

Pilot performance:

172 total journeys

1,506 hours of active cooling (62+ days)

~50% utilization, with room to scale further using the same fleet

Temperature performance:

1 total cooler excursion across all journeys

Occurred during extreme external heat (141°F vehicle trunk)

Internal temperature still held at -16°C (expected -20°C)

When used as expected, all other trips stayed within spec: despite frequent lid opens, long routes, and mixed payloads.

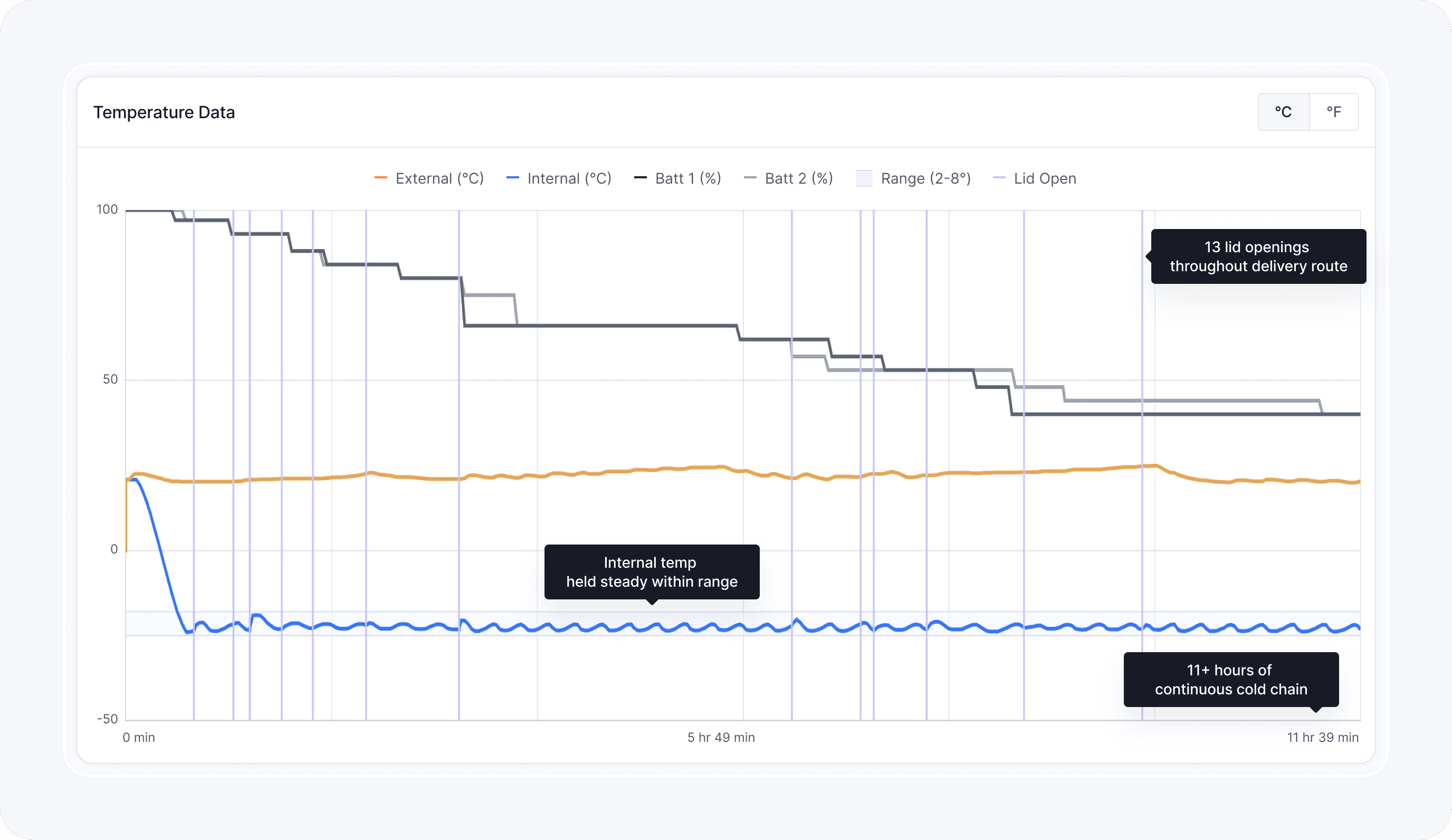

A closer look: frozen, all day

One route captured the operational reality Package Express sees every day.

9-hour transport window

Two full runs on the same route

13 lid opens

Frozen setpoint held at -20°C throughout

External temperatures reached 32°C (90°F)

Zero excursions

This happened during a normal workday, not a special test.

Source: Real journey data pulled from Artyc software

Driver-led improvement (powered by data)

The biggest operational win wasn't only temperature control. It was visibility.

With real-time logging, the ops team could review trips, identify patterns, and coach drivers using actual data. Common early issues, like insufficient charging or incorrect setpoints, became rare as feedback loops tightened.

Over the course of the pilot:

Preventable issues dropped by 74%

First 60 journeys: 15% had preventable issues (9 incidents)

Following 112 journeys: 4% had preventable issues (4 incidents)

The result: better outcomes without changing who does the work, but rather how it's supported.

What Package Express learned

Familiar workflows, fewer variables

Drivers adapted quickly. No dry ice. No gel packs. Just charge, load, and go.

One tool, all temperature ranges

Frozen, refrigerated, and ambient transport were handled with a single platform. No reconfiguration, no repacking.

Data as a training tool

Lid opens, temp logs, and route data turned cold chain compliance into something the team could actively manage, not only audit after the fact.

Reuse, realized

With six coolers, Package Express completed 172 journeys, showing how even a small fleet can support high-frequency operations.

The takeaway

This pilot showed what's possible when cold chain tools are designed for everyday routes rather than edge cases.

For Package Express, active cooling delivered:

Greater control in extreme heat

Less operational friction

Better driver accountability

A clearer path to scaling without adding complexity

And for teams running real routes, in real conditions, that's what progress looks like.

Interested in running a pilot? Contact us to learn more →

For questions about Package Express's experience with Artyc, contact Michael Salisbury at msalisbury@packageexpress.net